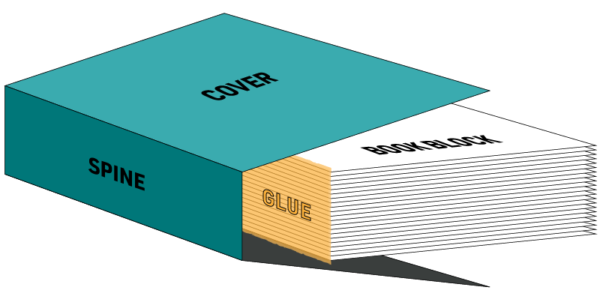

The most common type of book binding for commercially produced books is the perfect binding. What many publishers (and more than a few designers) don’t realize is that there is a choice of glues to use in assembling the bound book. The most common is EVA, but the newer and better choice is usually PUR.

Background

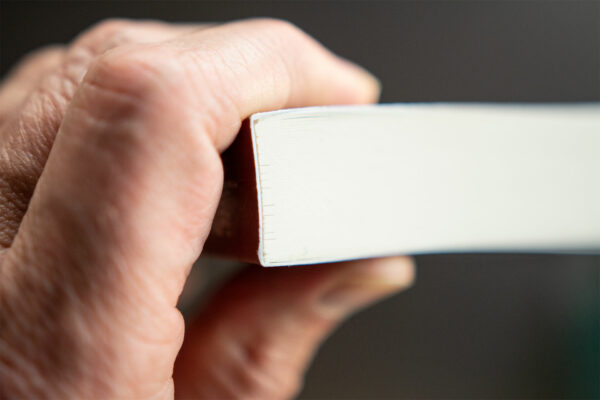

It is a simple and cost effective construction: the spine side of a stack of printed pages is roughed up, glued, and the scored soft cover wrapped around. This secures the pages together and to the cover in one step. Once the glue is set, the book’s three remaining sides are trimmed, cover and pages, creating the so-called “perfect” edges.

The result is clean and compact.

Why the choice of glue?

Ethylene-Vinyl Acetate (EVA) has been the go-to glue for perfect binding for many years. Most people know this as simply “hot melt” glue—the sort of thing you can buy in a craft store in sticks to put into your glue gun. Industrial versions for book binding is formulated a little different, but it is the same principle.

It is inexpensive, somewhat flexible, and far superior in flexibility to the animal (collagen) glues that were used previously. The fact that it can be heated, cooled, and reheated makes both manufacturing and cleanup easier. Many small print shops that offer in-house book binding use EVA glue.

But EVA isn’t perfect.

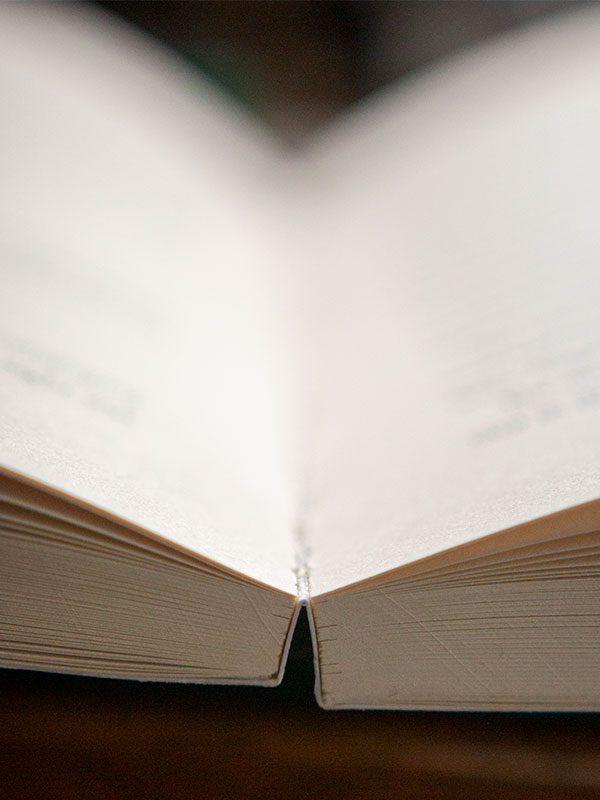

Although far less of a problem than in older perfect bound books, EVA glued books are still subject to “cracking” if you try to open them too far (or open them while too cold). Once broken, the spine will likely have a crack or crease in it, and the pages near the break are more likely to come free.

Enter polyurethane reactive (PUR) glue. The PUR formulation used in book binding is also a hot melt glue. But unlike EVA, once PUR is heated and cooled, it is set for life; it cannot be reheated or remelted. This is because the PUR curing process, absorbing moisture from the air, to create an elastomeric film.

PUR is significantly stronger and more flexible than it’s EVA counterpart, even as it is applied thinner. For this reason, it is generally considered a better glue for book binding.

But there is a drawback.

Because it sets forever when cooled, it is more difficult for the bindery to work with. It likely leads to more waste, especially for a printshop that only does occasional bindings, or short runs—any glue that has been heated has to be discarded at the end of the shift. And for these reasons, a PUR bound book will tend to be slightly more expensive than an EVA bound book.

But these are issues for the production side of things, and the superiority of the end product justify this inconvenience. I would generally always recommend to clients to go with a printer/binder that uses PUR glue for perfect bound, as well as glued case-bound books.

So why is EVA still used?

Since EVA is less expensive to buy and use, it is still common in the production world. Especially in production facilities catering to high volume, low cost production.

EVA is still found in the other end of the spectrum, as well: print-on-demand services. Usually the binding glue is not specified with POD operations such as Amazon’s KDP or Ingram’s IngramSpark—both using a worldwide network of automated production facilities to produce books. Since it isn’t specified, assume they are doing the least expensive option—very likely EVA.

And while EVA is not terrible, since there is a better option out there, PUR glue is my preference if I have the option.

Leave a Reply

You must be logged in to post a comment.